Electrical testers play a crucial role in ensuring safety and efficiency in electrical work. Whether in homes, offices, or industrial settings, these tools help identify electrical issues before they become dangerous. Understanding the different types of electrical testers, their features, and their uses can empower both professionals and DIY enthusiasts. This article will explore various aspects of electrical testers, providing detailed insights into their significance and operation.

What Are Electrical Testers?

Electrical testers are devices that help measure voltage, current, resistance, and continuity in electrical circuits. They come in various types, including multimeters, voltage testers, and continuity testers. Each type serves a unique purpose while ensuring electrical systems function safely and efficiently.

The Importance of Electrical Testers

Electrical testers are essential for several reasons. First, they help detect faults in electrical circuits, preventing potential hazards. A loose wire or a faulty connection can lead to short circuits, which may cause fires. By using an electrical tester, these issues can be identified early, minimizing risks.

Second, these tools facilitate troubleshooting. When an electrical device isn’t working correctly, identifying the problem is crucial. Electrical testers provide essential information that guides repairs. By knowing the voltage, current, or resistance, technicians can resolve issues more efficiently.

Types of Electrical Testers

Several types of electrical testers exist, each designed for specific functions. The most common types include:

- Multimeters: These are versatile tools that can measure voltage, current, and resistance. They are essential for both AC and DC circuits. Multimeters come in analog and digital forms, with digital models being more popular due to their ease of use and accuracy.

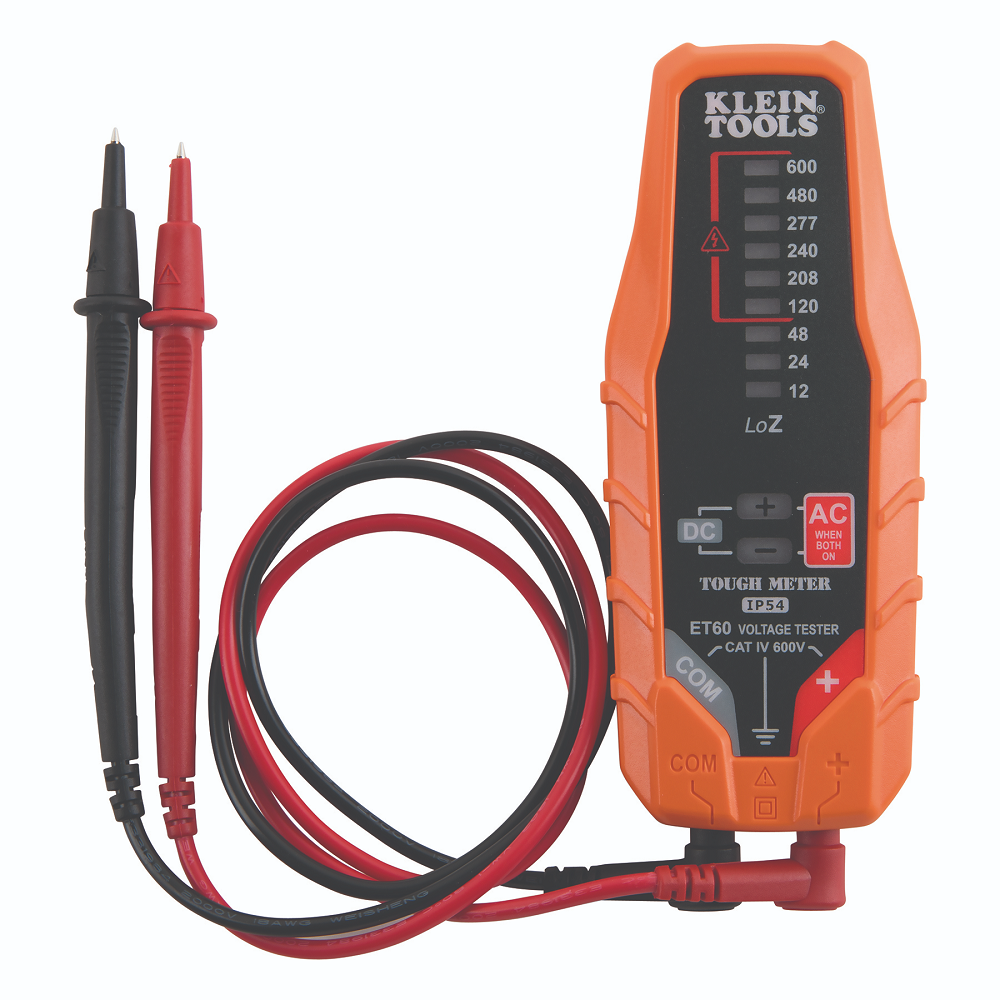

- Voltage Testers: These testers check if there is voltage present in an electrical circuit. They may come in non-contact and contact forms. Non-contact voltage testers are particularly useful because they allow users to detect voltage without touching the wires.

- Continuity Testers: These devices check if there is a complete path for current to flow. A circuit with no breaks or faults will show continuity. If a device does not register continuity, it indicates a problem somewhere in the circuit.

- Clamp Meters: These specialized testers can measure current without needing to break the circuit. They are particularly useful for measuring high currents safely.

How to Use Electrical Testers Safely

Using electrical testers safely is just as important as knowing how to use them. Here are some guidelines to follow:

Step 1: Read the Manual

Before using any electrical tester, it is essential to read the user manual. Each tester has its unique features and operational methods, making it crucial to understand how to use it properly.

Step 2: Wear Protective Gear

Safety gear protects against electrical shock and other hazards. Wearing insulated gloves and safety goggles is advisable when working with electrical systems. This extra layer of protection can make a significant difference.

Step 3: Turn Off the Power

Before testing electrical circuits, ensure that power is turned off. This reduces the risk of shock while making it safer to work on wiring. Always double-check that the circuit is dead using a voltage tester.

Step 4: Properly Set Up the Tester

For devices like multimeters, ensure that it is set to the correct measurement type before testing the circuit. This prevents damage to the tester and ensures accurate readings.

Step 5: Follow Procedures

Always follow proper procedures while testing. For instance, when measuring voltage, connect the probes correctly. Failure to do so can lead to incorrect readings or damage to the tester.

Step 6: Keep Testers in Good Condition

After use, store electrical testers in a dry, safe place. Regularly check their condition, including the probes and batteries, to ensure they function correctly when needed.

Troubleshooting Common Electrical Issues with Testers

Electrical testers are invaluable when it comes to troubleshooting common electrical problems. Here’s how to use them effectively:

Identifying Faulty Circuits

When a light fixture does not work, the first step is to check for voltage using a voltage tester. If the tester indicates that there is no voltage, the issue could be in the circuit, the switch, or the fixture itself. After confirming no voltage, check the wiring connections to ensure they are tight and secure.

Checking for Shorts

If a circuit breaker trips frequently, there may be a short circuit. Use a multimeter to check the resistance across the circuit. A reading of zero ohms indicates a short. Inspect wiring and connections to locate the fault. This often involves visually checking for damaged insulation or incorrect connections.

Confirming Ground Connections

Ground connections are vital for safety. Use a continuity tester to confirm that the ground wire has a solid connection. Place one probe on the ground wire and the other on a known ground point. A continuous beep or reading indicates a good ground connection. If not, inspect the ground wiring.

Testing Appliances

When an appliance fails, testing it directly can reveal issues. Use a multimeter set to measure voltage and test the appliance’s plug. If it shows voltage but the appliance does not work, the problem may lie within the appliance. If no voltage is present, check the wall socket for issues.

Monitoring Circuit Loads

In industrial settings, monitoring circuit loads is critical. Clamp meters make this process easy by allowing current readings without breaking circuits. This information helps in ensuring circuits do not exceed their load capacity, preventing overheating and potential fires.

Advances in Electrical Tester Technology

Recent advancements in technology have enhanced the functionality and usability of electrical testers. Below are some modern features and benefits:

Smart Features

Today’s electrical testers often come equipped with smart features. Many devices connect to smartphones, allowing users to log readings and share data easily. This feature is especially beneficial for professionals who need to provide reports to clients.

Enhanced Safety Features

Newer testers often include enhanced safety features, such as automatic shutdown to conserve battery life and alerts for high-voltage situations. These advancements help reduce the margin for error and promote user safety.

Improved Accuracy

Modern electrical testers offer improved accuracy in readings. Digital multimeters, for example, can provide more precise measurements, reducing the chances of incorrect diagnoses. This feature is critical for professionals who rely on accurate data for troubleshooting.

User-Friendly Design

Innovative designs make electrical testers easier to use. Many models now feature larger displays with backlighting, making them accessible even in dim conditions. Ergonomic grips and intuitive controls simplify the testing process, improving user experience.

Integration with Other Tools

Some electrical testers can integrate with other diagnostic tools. For example, some multimeters may work alongside clamp meters or thermal imagers. This integration allows comprehensive analysis of electrical systems, leading to more efficient troubleshooting and maintenance.

Choosing the Right Electrical Tester for Your Needs

Selecting the right electrical tester can feel overwhelming due to the variety of options available. Here are some steps to simplify the decision-making process:

Assess Your Needs

First, determine what tasks you will be using the tester for. If you only need to check household outlets, a basic voltage tester may suffice. However, if you’re involved in more complex electrical work, a multimeter with a range of capabilities would be a better investment.

Consider the Types of Circuits

Think about the types of circuits you will be testing. For AC circuits, a true RMS multimeter is ideal, as it provides accurate readings even with non-linear loads. If you often work in tightly packed spaces, a clamp meter might be more practical since it can measure current without disconnecting cables.

Check for Certifications

Ensure the electrical tester meets industry safety standards. Look for certifications such as CAT ratings that indicate its safety for specific types of electrical work. Choose testers that align with the highest safety standards to protect yourself from electrical hazards.

Explore Features

Identify which features are essential for your work. For professionals, features like data logging, Bluetooth connectivity, and backlit displays may be beneficial. For home use, simplicity and ease of use might be more important.

Read Reviews

Before making a purchase, read reviews from other users. Real-world experiences can provide insight into the tool’s reliability and performance. Consider both positive and negative reviews to gauge the tester’s overall effectiveness.

Maintaining Your Electrical Tester

Regular maintenance ensures that electrical testers operate at peak performance. Here are essential maintenance tips to consider:

Clean the Testers

Keeping electrical testers clean helps prevent damage and ensures accurate readings. Regularly wipe down the exterior with a dry cloth to remove dirt and grime. For probes, use isopropyl alcohol to clean any corrosion or debris that may interfere with measurements.

Inspect for Damage

Before each use, inspect your tester for visible damage, such as cracked displays or frayed wires. If any issues are found, address them immediately or replace the tool. Operating with damaged testers can lead to unsafe situations or inaccurate results.

Check Battery Status

Many electrical testers run on batteries, which should be checked regularly. Low batteries can affect performance. Replace batteries as needed, following the manufacturer’s recommendations for the correct type and size.

Store Properly

Store electrical testers in a dry, safe location to protect them from moisture and physical damage. Many testers come with carrying cases or pouches, which should be used to prevent wear and tear.

Perform Calibration

Some advanced testers may require periodic calibration to ensure accuracy. Follow the manufacturer’s guidelines regarding calibration schedules and methods. This process is critical for maintaining the tester’s precision, especially in professional settings.

Conclusion: The Value of Electrical Testers

Electrical testers are invaluable tools that contribute to safety and efficiency in electrical work. By understanding how to choose and use these testers correctly, you can protect lives and property from electrical hazards. Advance your knowledge and skills to enhance your expertise in this crucial area, whether you are a professional or a home DIY enthusiast. Regularly maintaining your testers ensures they remain reliable, providing the utmost safety in all your electrical endeavors. Embrace these tools as essential components of your electrical toolkit, and prioritize safety and precision in every task you undertake.